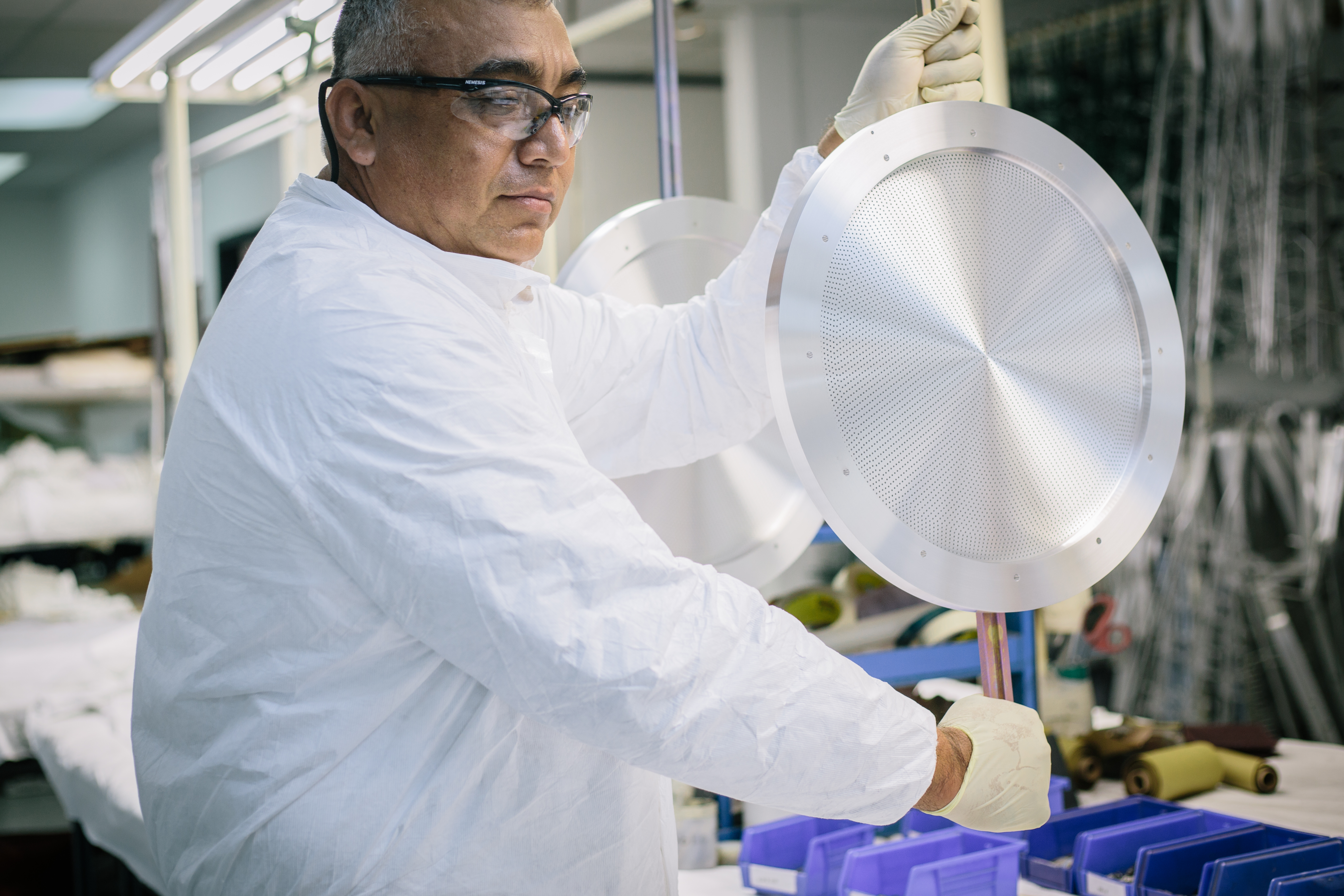

Semiconductor-Grade Anodization, Plating & Cleaning

Following the machining process, NxEdge offers a variety of surface treatments (and tank sizes) that improve part performance and extend part lifecycles.

Combined, our Boise, San Carlos, and Santa Clara sites offer more than 15,000 square feet of anodizing tanks.

We are able to service a comprehensive array of part sizes by maintaining both small and large anodizing tanks, and our numerous qualifications allow us to integrate anodizing with our machining and coatings.

Our Process

Tested in plasma environments by both equipment and device manufacturers

Continuously increases anodic coating capabilities through partnerships with leading equipment manufacturers, who face increasingly challenging applications for their most advanced systems

SPECIFICATIONS and TANK SIZES

Plating

To compliment our anodizing capability, our Santa Clara and San Carlos sites offer plating services that enhance part performance and life cycle.

With over 10,000 square feet of plating lines and a variety of plating materials, we are capable of addressing many specific applications.

ELECTROLESS PLATING

Mid- and high-phosphorous Nickel

Cadmium replacement coating

Exclusive licensee (northwest region) of Dicronite Dry Film Lubricant

Nickel/Boron

Boron Nitride/Nickel Composite

Gold

PRECIOUS METAL PLATING

Gold (hard, soft, and reflective)

Silver

Platinum

Gold/Tin Alloy

Post-Anodize Cleaning

NxEdge offers revitalization and cleaning service solutions that reduce surface contamination, eliminate degradative processing steps, and extend component life.

After the initial anodization and coating process, our cleaning capabilities improve adhesion, reduce contamination, and ultimately prepare a part for advanced coatings and a final clean.

We integrate SPC and QA processes into our operations to ensure conformance with specifications, and we continuously upgrade our products and anodization, coating and cleaning services to meet the increasingly demanding process requirements of our customers.

Post-Anodize Cleaning

Capabilities at Santa Clara and San Carlos

Minimal impact on plated and bare aluminum surfaces

Multiple tank sizes accommodate a wide range of parts

Complete chemical laboratory with in-house chemical tracking and analysis

0250-30100 cleaning specification qualification

Class 1000 Clean Room at San Carlos

Class 100 and Class 1000 Clean Room at Santa Clara