Cutting-Edge Surface Cleaning & Coatings Featuring ICPMS Analytics

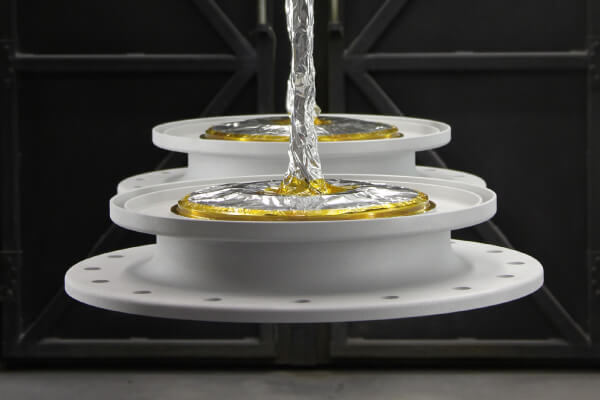

NxEdge offers both industry standard and process-specific fluoropolymer coatings. Fluoropolymer coatings are well-suited for use in wet chemical process applications because they are highly resistant to corrosive chemicals and can withstand working temperatures of 150-315° C. Our Fluoropolymer coatings have proven beneficial in semiconductor wet processing and other highly acidic environments.

Application

NxEdge provides multiple polymer and plastic coatings. Some of our standard coatings are:

Materials Engineered & Developed

Unique Combination of Capabilities

NxEdge’s final clean capabilities reduce particulation, contamination, and trace metals on critical semiconductor equipment components — allowing for better part performance during chamber use.

We offer a proprietary cleaning process that preserves coating integrity while covering an extensive set of products and surfaces with approvals across several OEM and IDM vendors.

For both new and refurbished parts, NxEdge final clean minimizes post-PM tool recovery time, ultimately extending the life of critical parts.

FINAL CLEAN

Instruments & Tools

Materials Characterization

Spectrometry

Coating Thickness Measurement

Particle Counting

Atomic Composition Analysis

PRocesses

Certified coating and manufacturing operations (ISO 9001:2015 at Boise, San Carlos, and Santa Clara)